Energy efficiency

Integrated Air Protection System with Energy Recovery

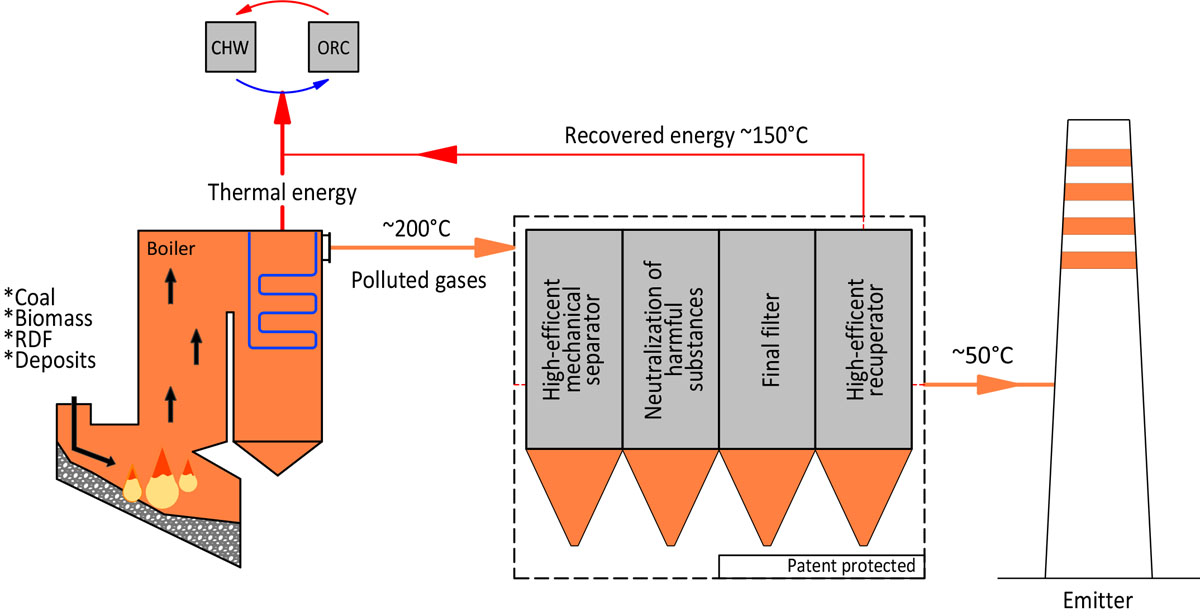

Complex approach to the fumes cleaning issue and energy recovery is ensured by designed by INSTAL-FILTER SA compact system applied when solid fuels (coal, biomass, RDF, sludge) are combusted.

MECHANISMS OF ACTION AND STRUCTURE

The Integrated Air Protection System with Energy Recovery intended for solid fuels combustion, in form of a compact set of devices located between a heat source and an emitter; it enables, because of its small external dimensions, fastening it within existing infrastructure. Integrated system receives fumes originating from combustion of solid fuels and, at the first stage, it separates solid pollutants in order to reduce post-reaction wastes. At the second and the third stage there is supplied sorbent and there takes place reduction of acid compounds as well as final separation of solid particles. De-dusted and neutralized fumes are subject to the fourth stage where there takes place a deep recovery of thermal energy which substantially improves heat balance of the boiler. Optionally, the system may be equipped with Nox, HF, HCL, heavy metals, dioxins reduction system.

ADVANTAGES

ADVANTAGES

Thanks to efficient de-sulfuring process the system enables reduction on fumes temperature at the outlet from the system up to approx. ˜ 50°C without a risk of increase in corrosion.

Innovation of the system is complex cleaning of fumes and residue energy recovery in the framework of a single compact device.