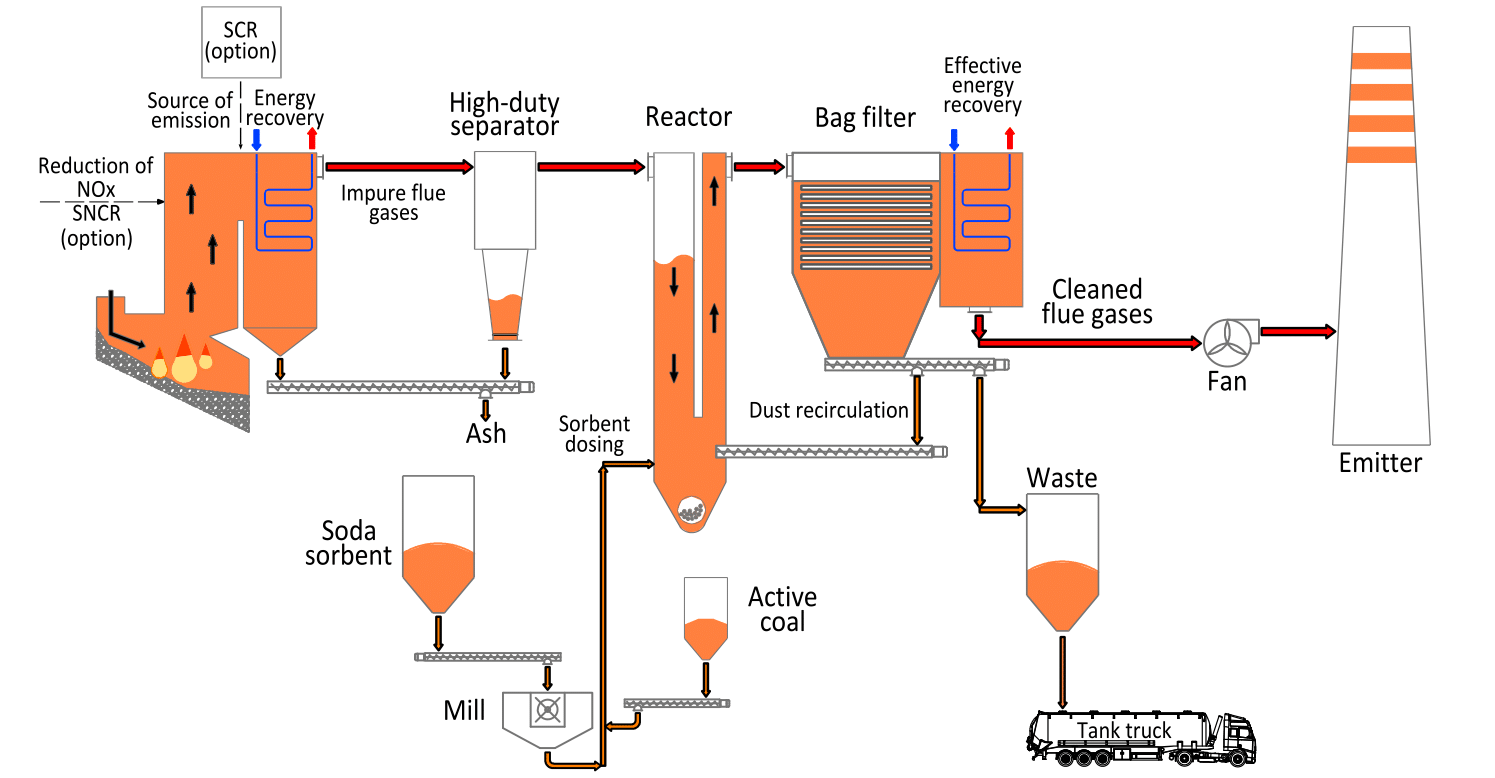

Desulphurisation with mechanical reactor

FIELD OF APPLICATION

Systems with mechanical reactor used by INSTAL FILTER SA are characterized by simple design. They work perfectly well in the processes of desulphurisation of stoker-fired boilers and provide obtaining reductions required by the IED Directive, when using different grades of coal. The solutions based on mechanical reactor are dedicated to small and medium capacity boilers, featuring variable operating conditions.

Both lime, and soda may be used as sorbent for these technologies.

PRINCIPLE OF OPERATION

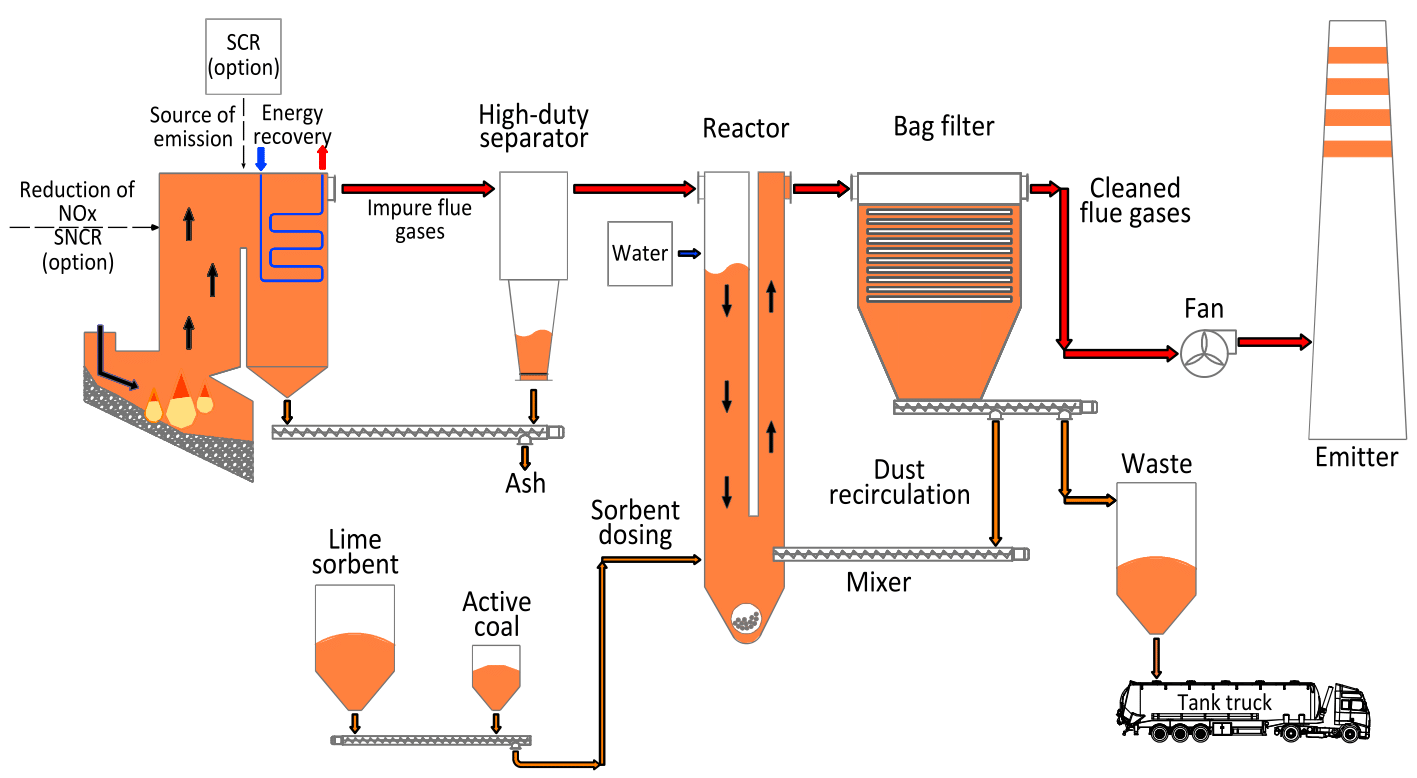

The basic components of the system using mechanical reactor are:

- conditioning drum, which guarantees uniform distribution of reagent in the stream of flue gas,

- desulphurisation product recirculation system, reducing the costs of operation and flue gas conditioning system providing the proper temperature

- and humidity of flue gases, which determine the proper course of the process.

The flue gas stream directed to IOS is brought to upper part of the reactor through the non-desulphurisation flue gas ducts. Conditioning and homogenisation of flue gas stream takes place in the reactor. Flue gases in the reactor interact with a sorbent, and then flow to a bag filter. The cake deposited on filter bags consisting of mixture of dust and post-reaction product create the natural filtration layer, in which flowing substance is subject to final cleaning from dust and gaseous impurities.

BENEFITS:

- Dedicated to small and medium capacity boilers.

- Meets the requirements of BAT and IED for a fuel of good quality

- High flexibility of system operation

- Low costs of operation

- High availability

SYSTEMS WITH MECHANICAL REACTOR (DUST, SOx, NOX) ON LIME SORBENT

Desulphurisation effectiveness at the level of ca. 90%

SYSTEMS WITH MECHANICAL REACTOR (DUST, SOx, NOX) ON SODA SORBENT

Ability to reduce of up to 100% of SOx / Ability to recover energy