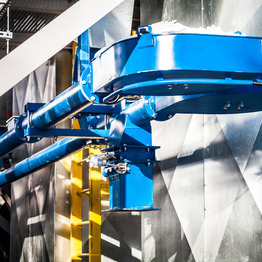

Dust collection system

APPLICATION AREA

Dust reception (collection) systems are necessary equipment of each dust-extracting installation. They are intended to remove dusts from chutes of the devices operating at pressures different from the atmospheric one. They enable emptying them without decompression or tight closure of a containers with dust.

We assure proper selection of a device adjusted to particular application.

ADVANTAGES

- simplicity of service and maintenance

- modern structural solutions assuring great reliability and low noise emission rates.

- support provided by experienced experts in the field of selection of concrete device to individual application.

- for explosive dusts some of the devices (dispensing units) can be offered in ATEX version.

Dosing valves

A gap valve is a simple and reliable shutting-off device. It is designed to remove dusts from containers operating at sub-pressure without a decompression risk. It is the most frequently applied by us e.g. beneath mechanical dust extracting units, cyclo-filters and bag filters. Basic element of a gap valve IF150 is a replaceable rubber element. This is very important since during operation, as an effect of sub-pressure, internal parts of lower part of the rubber element of the valve adhere tightly to each other. In this way, air can't penetrate the interior and dust can't leave the interior. After relevant quantity of dusts gathers over the rubber element (to equalize the sub-pressure), it is opened and dusts are ejected. It lasts till the sub-pressure in the valve closes it.

We offer two types of valves

- IF 150 R in a canvas housing, discharge of dust into a typical wastes container.

- IF 150 S in a metal housing, discharge of dusts into a transporting device.

Each of the type can be equipped with the following rubber element:

- C variant - made of EPDM rubber, characterized by thermal resistance 160°C

- B variant - made from silicone rubber, characterized by thermal resistance 400°C

Simple structure, no need for a drive and reliable rubber elements makes that the dosing valves are widely applied in the industry within our de-dusting valves.

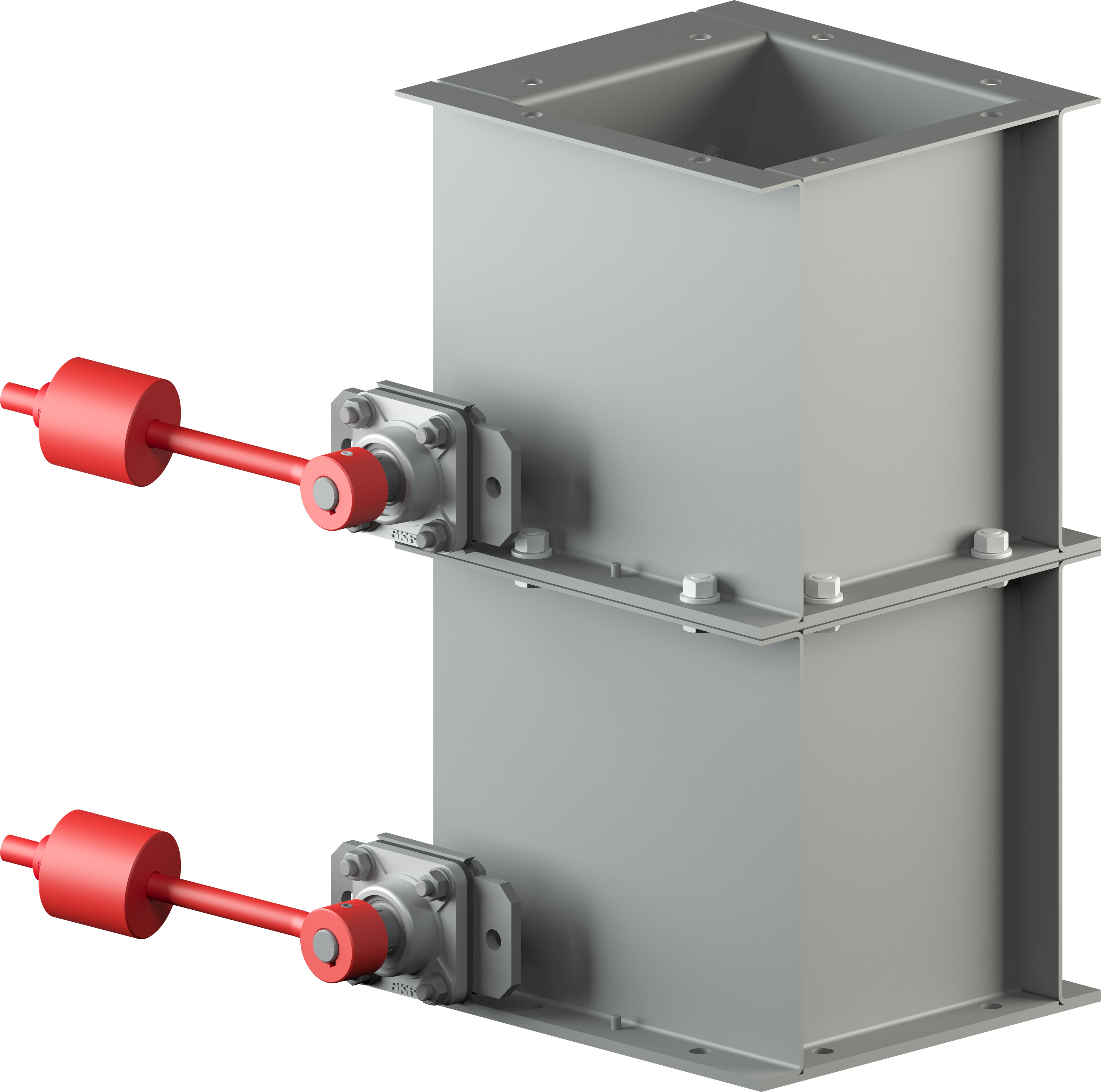

Swinging hatches

Swinging hatches can operate at the sub-pressure and at the over-pressure side of an installation - it depends on type of applied solution (hatches without a drive at the sub-pressure side, hatches with a drive at the sub-pressure / overpressure side). Standard device we offer is a double hatch.

Double swinging hatch without a drive

Device comprises a body and inlet and outlet flanges (square section). Inside the body there are two throats, through hole of which is closed by means of rotary hatches. They are equipped with levers with metal loads on them. Dusts, which go through the device, because of its weight, open the first hatch and, after closing it, another one. Synchronization of opening of the hatches and pressure on the throat is adjusted by relevant setting of loads on both of the hatches.

Double swinging hatch with a drive

In case of this solution there takes place enforced synchronization of swinging hatches opening. It takes place by means of motor-reducer assembly on axis of which there are fastened special cams. Their movement warrants setting of hatches - while one closes upper throat, the second one is open and vice versa. Such operation warrants 100% removal of dust without decompression. In case of a few solutions and additionally, in case of limited space, apart from double-hatch we apply single hatches.

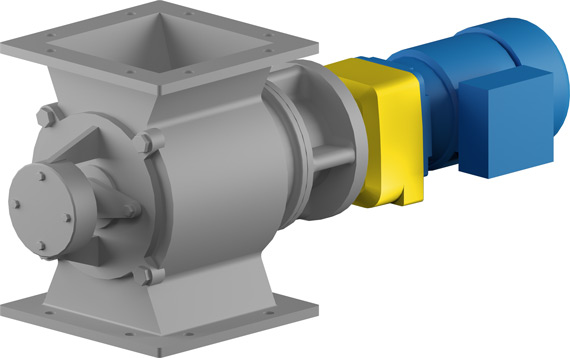

Rotary valves

Rotary valves may operate at the sub-pressure side and at the over-pressure side of an installation. When emptying, dust goes via inlet hole into blades of the valve and, after they turned, it is ejected via outlet hole. Emptied cells of rotating drum reach the inlet hole again and take another portion of dust. This cycle repeats regularly till the rotary valve drive is switched off. After stop of the drum the rotary valve plays a role of valve shutting off flow of dust and air. Flow of dust between inlet and outlet takes place without decompression.

Body and blades of the rotary blades are made of cast-iron or steel. For materials, which wipe off the interior, devices can be made of abrasion-proof materials. In order to avoid de-compression during operation of the rotary valve, its blades can be additionally equipped with replaceable sealing. As a standard, to drive the rotary valve drum there are used moto-reducer assemblies.

Among a series of types offered by INSTAL-FILTER SA we have rotary valves of type: B, RV, NW and NP.

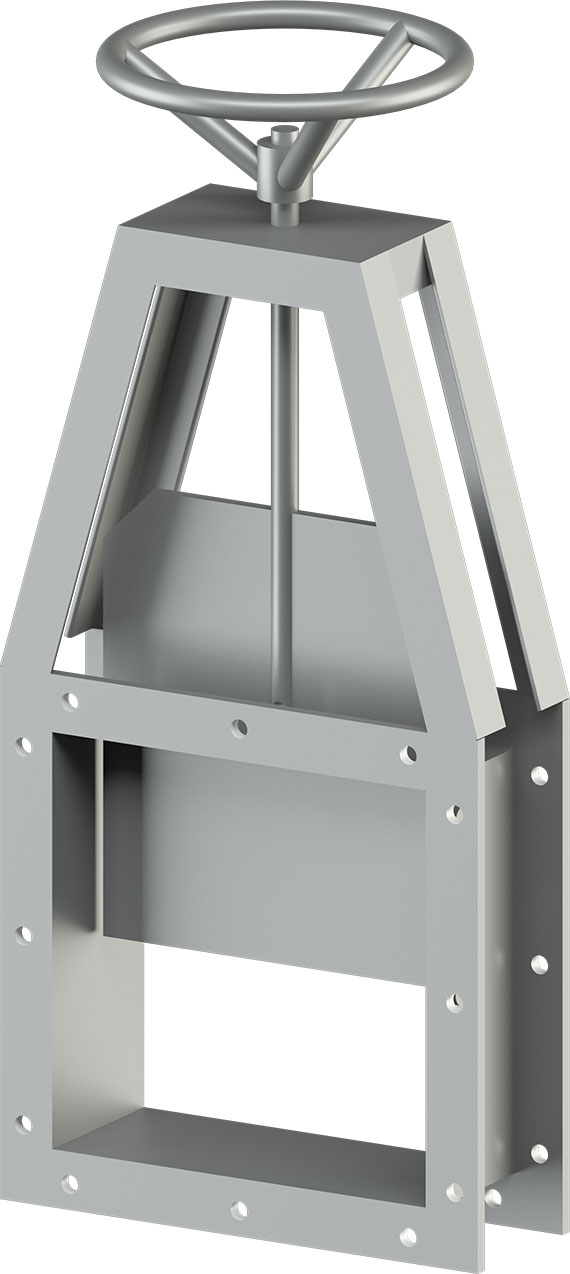

Dust gate valves

Dust gate vales, ZP type, are intended to shut-off systems with dusts and to empty them later. By gate valve opening range one may control speed of emptying.

Gate valves offered by us normally have a manual drive (manual wheel or a wheel with a chain for gate valve to which there is no access). They can also by equipped with an electric drive in form of a motor-reducer assembly. Element, which closes the interior of the gate valve body is a steel place with a leading system and seal of the plate protruding from the body.